Al-Mg-Mn Roof Plate is widely used in roof and wall systems of airport terminals, aircraft maintenance garages, stations and large transportation hubs, conference and exhibition centers, sports venues, exhibition halls, large public entertainment facilities, public service buildings, large shopping centers, commercial facilities, residential buildings and other buildings.

With the construction of large-scale public construction projects, there is a significant demand for the high-quality roofing materials. Profiled roof sheets made of aluminum magnesium manganese alloy (in short as Al-Mg-Mn metal roof panels ) are widely used in various types of buildings due to their advantages of quick installation and strong shaping ability. The Al-Mg -Mn alloy is lightweight, corrosion-resistant, and has a service life of over 40 years. Compared with steel plates, it is more economical, aesthetical, and practical.

According to the different types of the lock edge, the Al-Mg-Mn Roof Plates are divided into two categories, high standing edge and low standing edge.

High standing edge refers to an upright lock edge roof panel with a rib height of 65mm, providing better support and strength for the roof system. The thickness of Al-Mg-Mn metal roof panel is 0.9mm-1.5mm. The waterproof performance is particularly outstanding due to the high standing edge. This type of panels are more suitable for building projects with high waterproof requirements, such as public facilities, commercial buildings, etc. In addition, it has stronger snow and wind load capacity, making it suitable for large-span buildings such as large sports arenas, train stations, airports, etc.

The low standing edge Al-Mg-Mn Roof Plates refers to an upright lock edge roof panel with a rib height of 25mm, commonly used in models such as 530. The commonly used thickness of this type of roof panel is 0.7mm-1.0mm, with lower vertical edges and relatively lightweight. Due to the low standing edge, additional waterproof measures such as sealant or special joint design may be required.

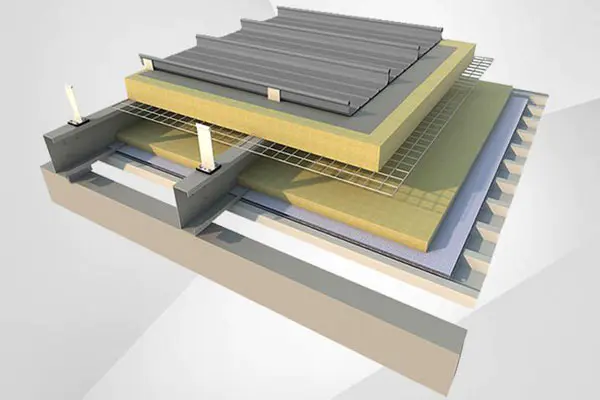

The common construction method for the roof is as follows:

1. Al-Mg-Mn metal roof panel adopts the specification YX65-430 of high standing edge metal panel,with the thickness of 0.9mm.

2. Bottom panel uses the specification YX15-225-900 of the galvanized profiled steel plate, with a thickness of 0.5mm.

3. Roof insulation layer adopts rock wool as the insulation layer, with the thickness from 50mm to 100mm.

4. Roof sound-absorbing layer uses glass fiber as the insulation layer, with the thickness of 50mm~100mm.

5. The secondary purlin of the Al-Mg-Mn metal roof panel is made of C-shaped galvanized steel with the specification C120 × 60 × 20 × 2.0.

6. Aluminum alloy roof fixed support is made of aluminum alloy material, with the height L=165mm.

7. Roof waterproof layer uses waterproof breathable membrane.